Vortakt Barrel Performance Series

bARREL pERFORMANCE sERIES

Barrel Manufacturing Resources

Barrel Blanks 101

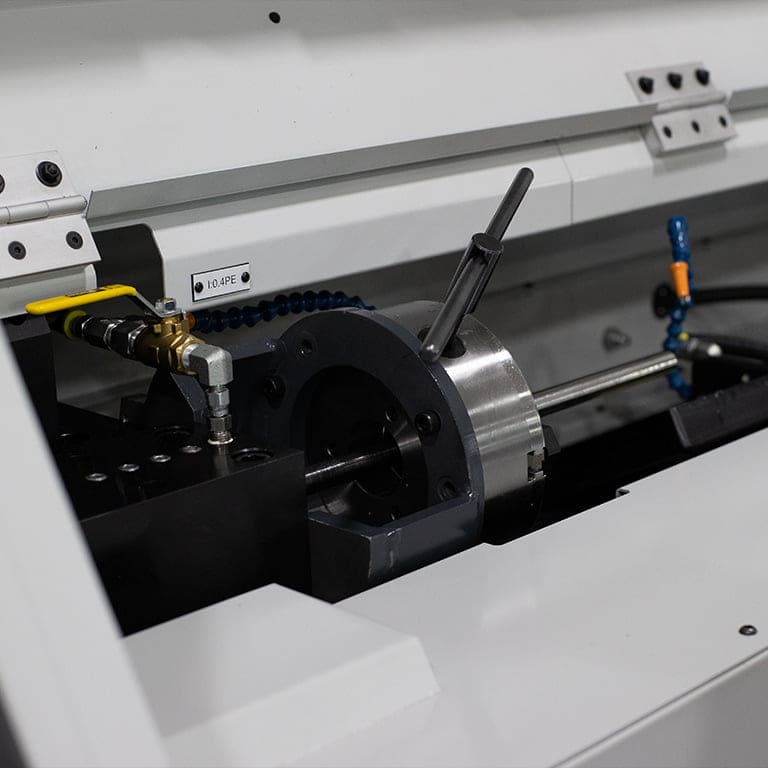

What is a Rifle Barrel Blank? Barrel blanks are cylindrical components of rifled firearms that will ultimately be machined to become a finished rifle barrel.

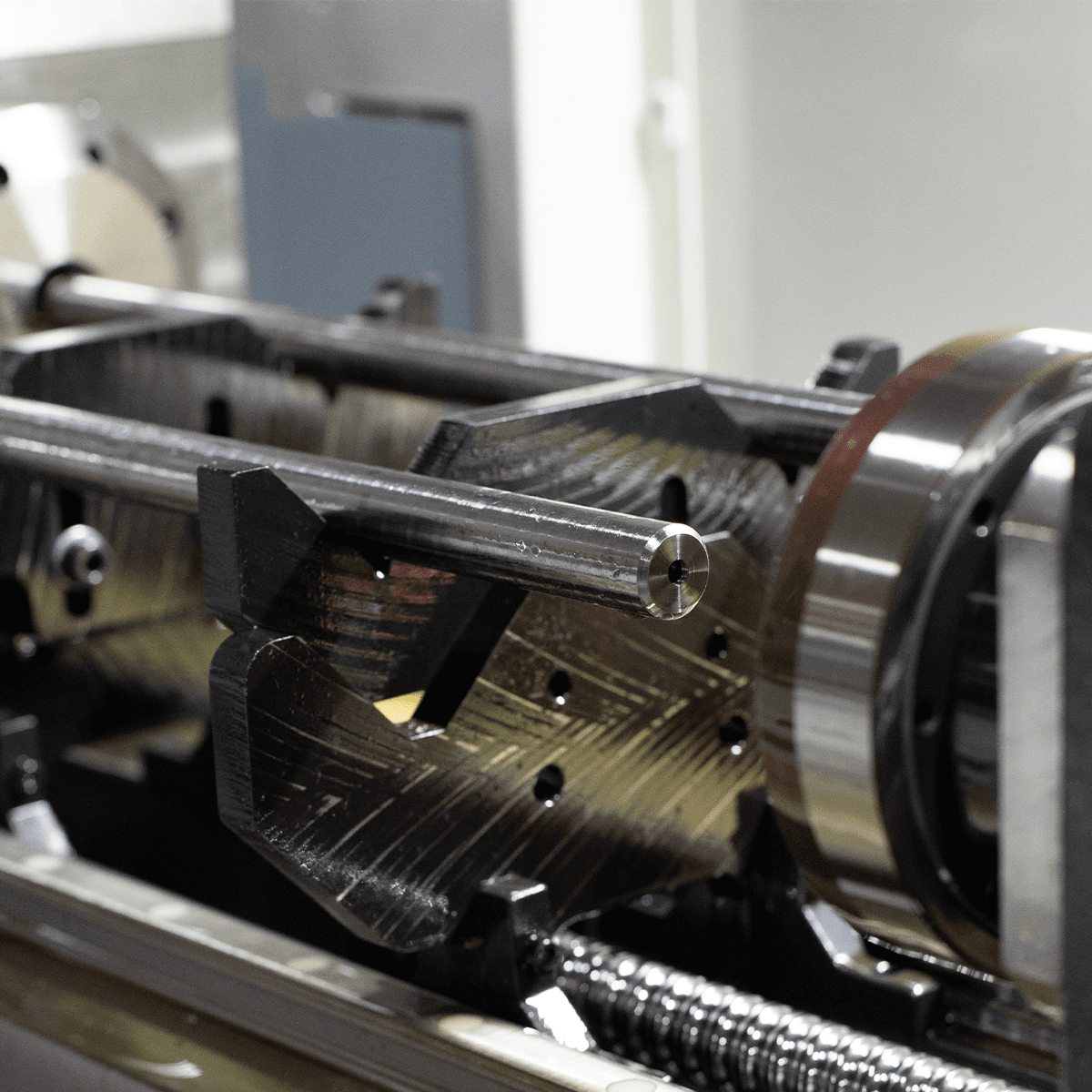

Rifling Types 101

Button, Single Point Cut, Broach, and Cold Hammer Forged: Which rifling type is the right fit for you?

Caliber List

Explore common caliber and twist options offered by Vortakt. Additional options are available by request.

Quality, Specifications, and Workmanship in the Barrel Manufacturing Process

Vortakt Barrel Works provides OEM barrels to top brands across the firearm industry. By effectively harnessing automation technology and adhering to engineering best practices, our

Stress Relieving in Barrel Manufacturing

What Effect Does Stress Relieving Have on a Barrel’s Performance? The phrase “stress relief” is a slang term that applies to a form of heat

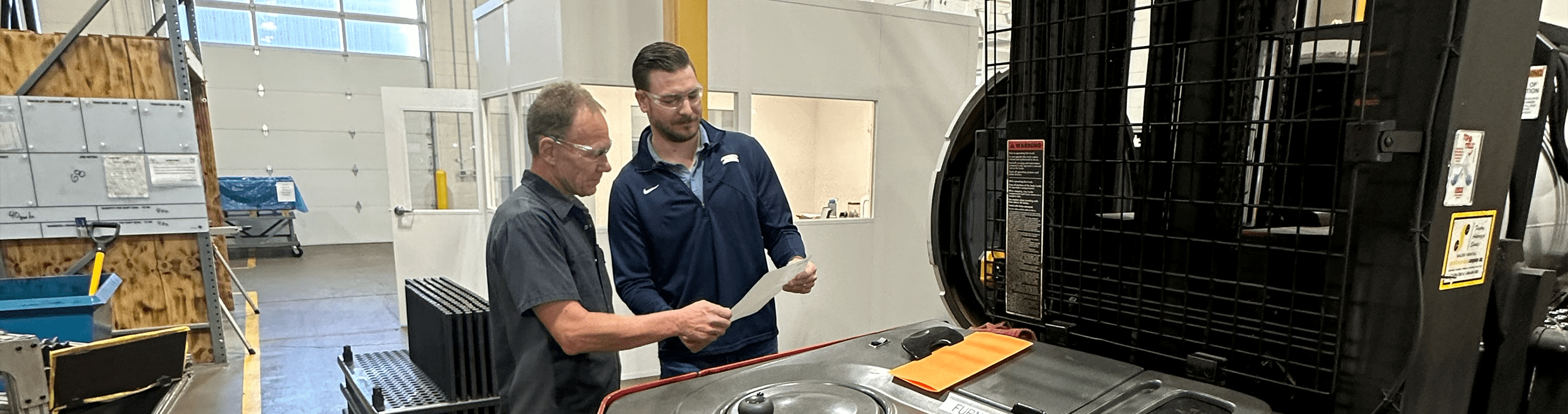

Vortakt Introduces Lean 5S Program with New Production Manager Hire

Marc Grischeau: Driving the Firearm Industry Forward Through Smart Manufacturing Why are we most excited about Marc’s arrival? He’s a critical ingredient in the recipe to

Air-drop Program